We have a new solution for you!

For Evaporators at Sugar Mills

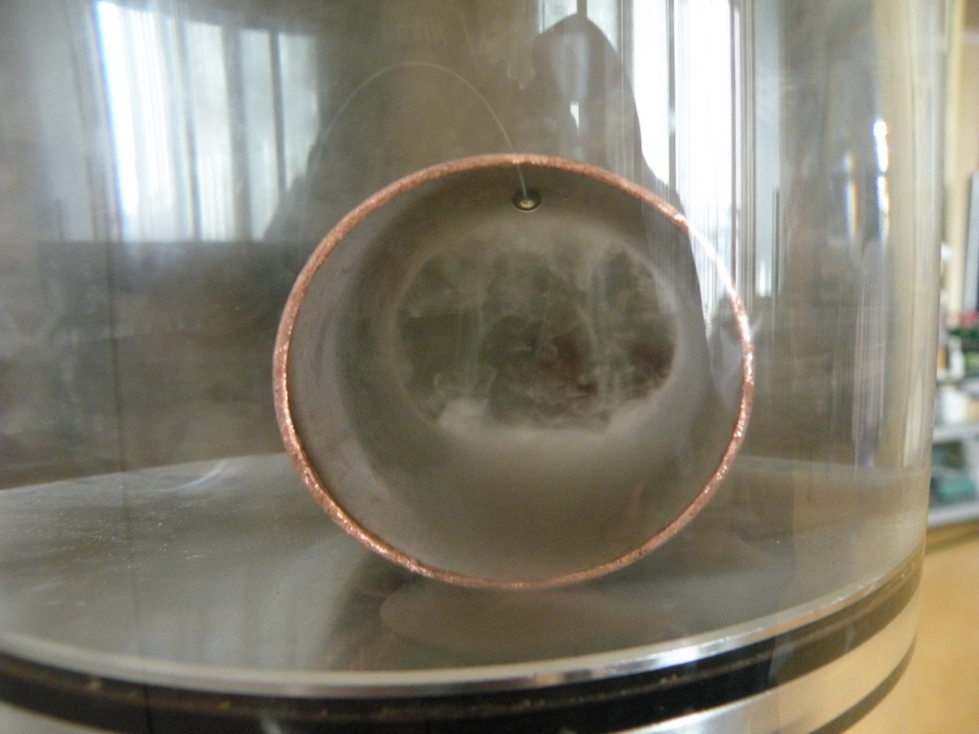

For the production of sugar from sugar canes or sugar beets, an evaporator is an essential facility to gradually convert sugar juice into syrup by evaporation. The sugar juice extracted from sugar canes or beets becomes more and more concentrated as it passes through a series of evaporators. However, in this evaporation process serious troubles, caused by scales forming in the tubes of evaporator, have been commonly reported from numerous sugar mills.

To remove these scales sugar mills need to periodically stop running their processing lines. Inevitably, there are no ways to avoid unwanted situations, such as reduced production or spending extra expenses for cleaning and environmental works. In addition, such a short cycle for cleaning leaves behind heavy maintenance and management works.

Many different types of scales form in the evaporator's tubes. The scales might be different from area to area depending on local soil types and weather conditions where the sugar canes or beets are cultivated.

Scales in steel tubes can be removed by hydrochloric acid, whereas those in copper tubes cannot because of corrosion. Although scales in copper tubes can be physically cleaned by high-pressured water, there are some severe safety issues in this method .

Even though various chemicals could be used for cleaning tubes in evaporators, these tubes, in reality, should be cleaned in short intervals (every 1-2 weeks) because these scales often grow in the tubes very rapidly. However, if the interval for cleaning can be extended, to more than three weeks, the sugar production would increase and additional economical benefits would be expected.

When our powerful and proprietary ultrasonic technologies are applied to the evaporators in your processing lines for sugar production, the formation of scales in the tubes are strongly prohibited. Those scales already developed in the tubes are also removed due to vibration and cavitation generated by unusually powerful ultrasonic sounds. As a result, if the cleaning intervals for steel or copper tubes in evaporators were greatly extended after the installation of our USP, sugar production at your mill would be remarkably increased and routine maintanance workload and cost for cleaning would also be greatly reduced.

Even though various chemicals could be used for cleaning tubes in evaporators, these tubes, in reality, should be cleaned in short intervals (every 1-2 weeks) because these scales often grow in the tubes very rapidly. However, if the interval for cleaning can be extended, to more than three weeks, the sugar production would increase and additional economical benefits would be expected.

When our powerful and proprietary ultrasonic technologies are applied to the evaporators in your processing lines for sugar production, the formation of scales in the tubes are strongly prohibited. Those scales already developed in the tubes are also removed due to vibration and cavitation generated by unusually powerful ultrasonic sounds. As a result, if the cleaning intervals for steel or copper tubes in evaporators were greatly extended after the installation of our USP, sugar production at your mill would be remarkably increased and routine maintanance workload and cost for cleaning would also be greatly reduced.

Simulation tests for the tubes in Evaporator 2 and 5 of Manuelita Sugar Mills in Colombia

Tube in Evaporator 2

Tube in Evaporator 5

Inside Scale Removal Process